The Process of Making Shatter: A Step-by-Step Guide

Hidden Gems: Unusual Museums in Amsterdam

06/14/2024

Cannabis and Creativity: How It Affects Artistic Expression

07/10/2024The Process of Making Shatter: A Step-by-Step Guide

Shatter making requires precision and care. If you’ve ever been curious about how shatter is made, this step-by-step guide will walk you through the process.

Step 1: Selecting the Cannabis

The quality of shatter starts with the cannabis used. High-quality cannabis flowers with a high concentration of trichomes (the resin glands containing THC, CBD, and other cannabinoids) are essential. The strain chosen can also impact the flavor and effects of the final product.

Step 2: Preparing the Extraction Equipment

Shatter is typically made using a solvent-based extraction process. Common solvents include butane and propane. The extraction equipment must be set up in a well-ventilated area with safety measures in place, as the solvents are highly flammable.

Step 3: Extracting the Cannabinoids

The cannabis is packed into an extraction tube, and the solvent is passed through it. As the solvent moves through the cannabis, it dissolves the cannabinoids and terpenes, creating a potent solution. This process must be done carefully to avoid any accidents due to the flammable nature of the solvents.

Step 4: Filtering the Solution

The solution containing the dissolved cannabinoids and terpenes is collected in a container. This mixture is then filtered to remove any plant material and impurities, ensuring that only the pure extract is left.

Step 5: Purging the Solvent

Now it’s time to remove the solvent from the extract. This is done using a vacuum oven, which applies heat and a vacuum to the solution, evaporating the solvent. The goal is to leave behind a pure, solvent-free concentrate. The temperature and duration of this process must be carefully controlled to maintain the quality and potency of the shatter.

Step 6: Cooling and Stabilizing

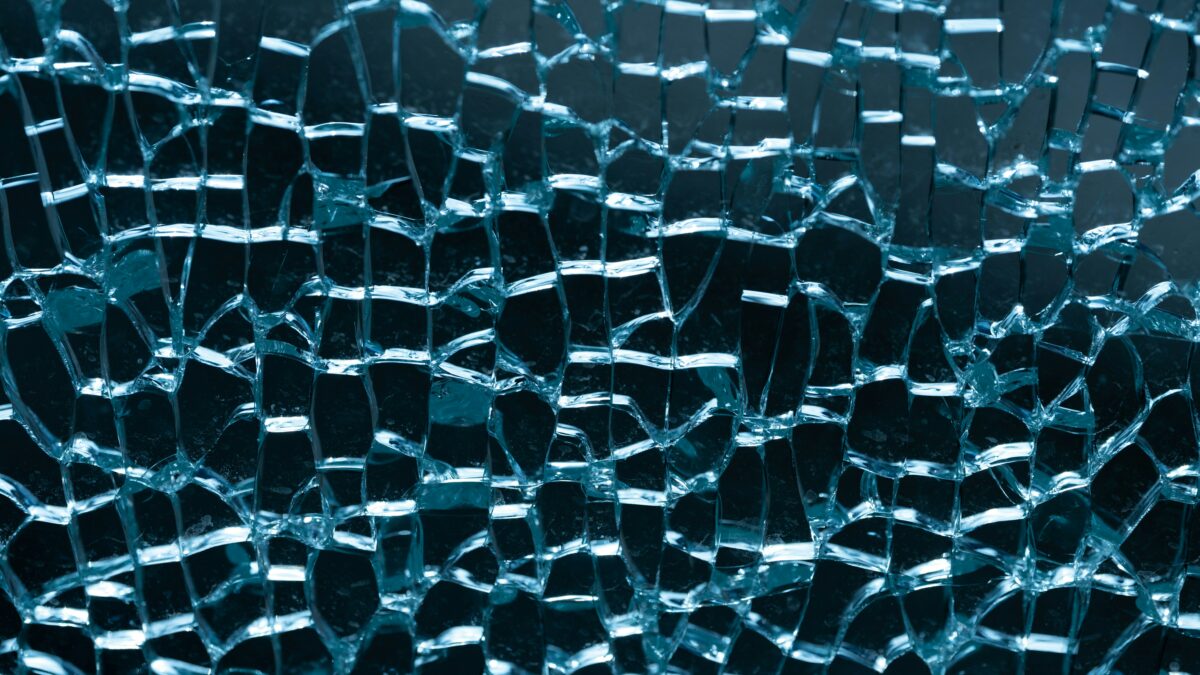

Once the solvent is purged, the remaining concentrate is cooled to allow it to harden. This is where shatter gets its distinctive glass-like texture. The cooling process must be gradual to ensure the concentrate stabilizes correctly, forming a clear, brittle sheet.

Step 7: Testing and Packaging

The final step is testing the shatter to ensure it’s free of solvents and contaminants and meets potency standards. After testing, the shatter is broken into smaller pieces and packaged. Proper packaging ensures the shatter remains fresh and retains its potency and flavor.

Tips for Quality Shatter

- Use high-quality cannabis: The better the starting material, the better the final product.

- Ensure proper purging: Incomplete purging can leave behind residual solvents, which can be harmful and affect the flavor and potency.

- Maintain a clean environment: Contaminants can compromise the quality of your shatter.

By following these steps, you can understand the detailed process behind creating this potent cannabis concentrate.